For workshops on shore and on board of a vessel we can offer a full line with electrical tools. The following brands are possible

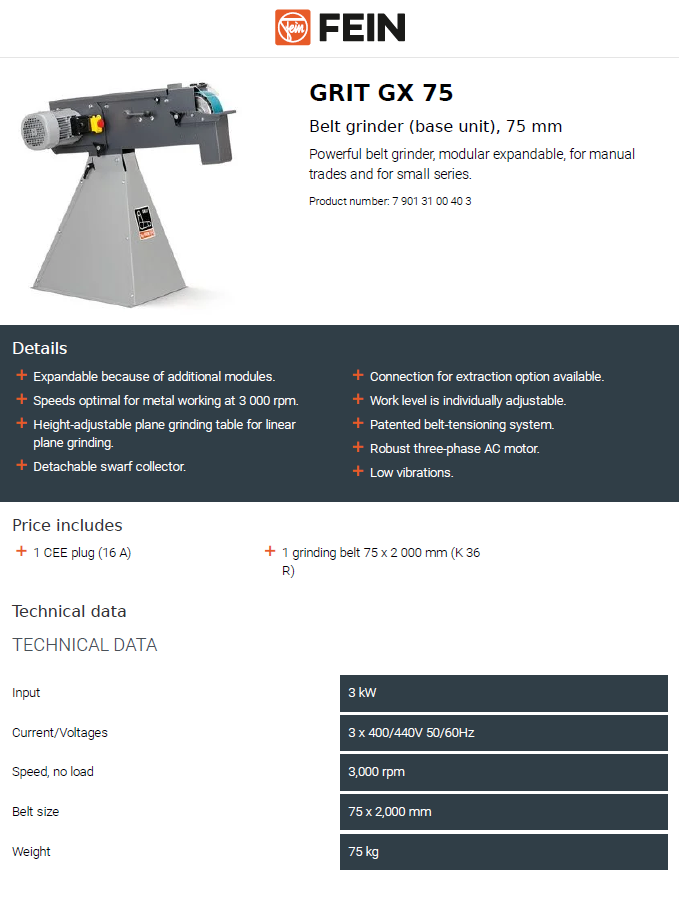

Grit Belt Grinders made by Fein

Developing problem solutions for metal processing – therein lies one of the core competences of FEIN. The GRIT belt grinder by FEIN is an application solution for stainless steel processing, metal engineering and heavy-duty grinding. GRIT has set standards in the belt grinder segment for 25 years. And you profit from the comprehensive know-how that is at the heart of two leading brand manufacturers.

Band Saws

From the Italian manufacturer Femi we offer several portable band saws. All can easily be used on 220-240V 50Hz. Different saw capacities are possible. The light weight makes this band saws a must have tool for on board of your vessel of on site. The saws are easy to manage and extremely safe to work with. Femi has also a complete range of electric workshop machines. Contact our product specialists for the possibilities.

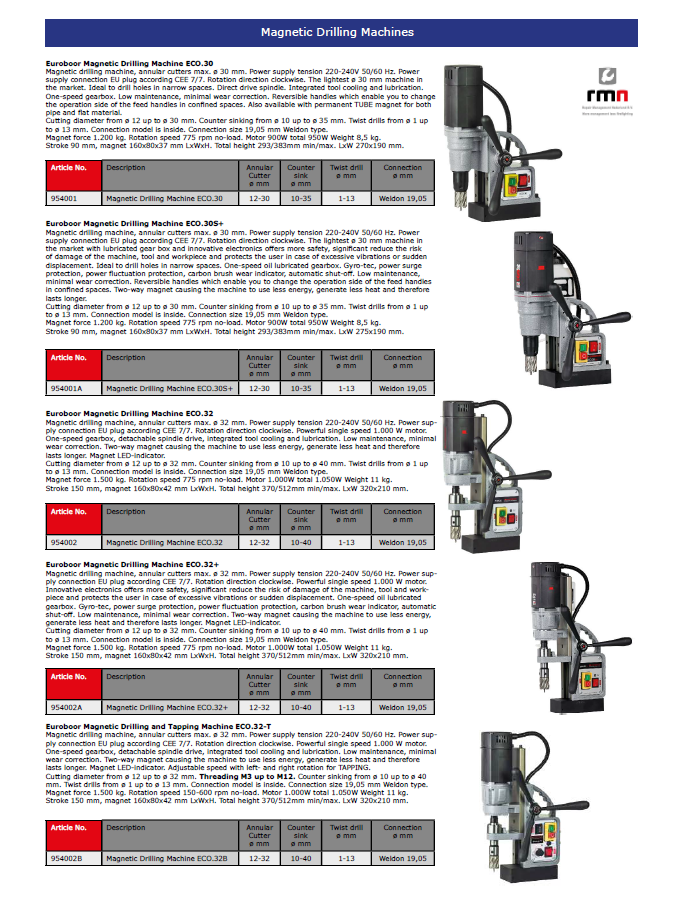

Euroboor Magnetic Drilling Machines

Euroboor is since the founding in 1977 specialized in developing, manufacturing and marketing of high performance Magnetic Drilling Machines. The range consist of machines with a drilling capacity from Ø 12 mm up to Ø 200 mm (with annular cutters). There are these days also machines with a vacuum attachement instead of magnetic and machines are avaialable in normal electric power, cordless 18V and pneumatic driven. Beside this there is a range of machines for bevelling, grinding and sawing. At the PDF you will find a part of the Euroboor range of Magnetic Drilling Machines.

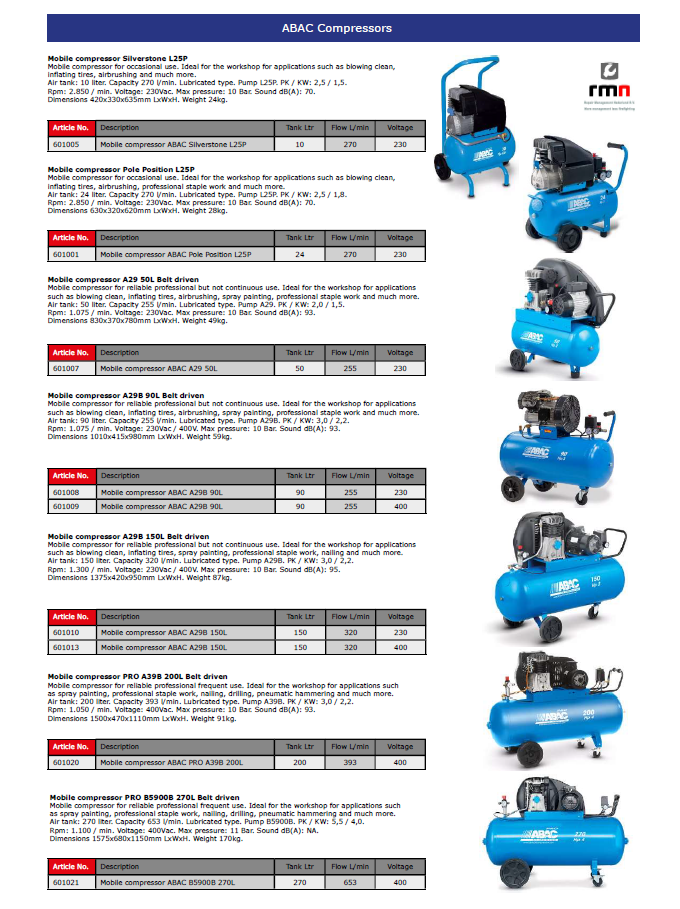

ABAC Compressors

ABAC Compressors is part of Creemers Compressors. ABAC is the compressed air specialist with high end technology to provide reliable compressors for all kind of applications. The professional compressors are used in many different industries. The range we as RMN offer here are mobile professional compressors. If other types of compressores are required please contact our sales department.

WISENT Metalworking Machines

Wisent machines has been specialist in the field of metalworking machines for over 25 years. The range of machines consist of band sawing machines, metal circular sawing machines, column drilling machines, column drilling- and thread taping machines, core drilling machines, belt grinding machines and bending tools.

THOMAS S.p.A.

Leader as Metal cutting Machinery Manufacturers (tubes, profiles, solid materials) since 1951. The wide set of products ranges from the traditional Circular Sawing machine to more modern Metal Cutting Band Sawing machines in the manual, semi-automatic, automatic and CNC, mainly through Hydraulic Machines technology. The Company are also Band Saw Blades suppliers of WAL-ZER brand for perfect metal cutting.