Miko Plaster® Polar Kit

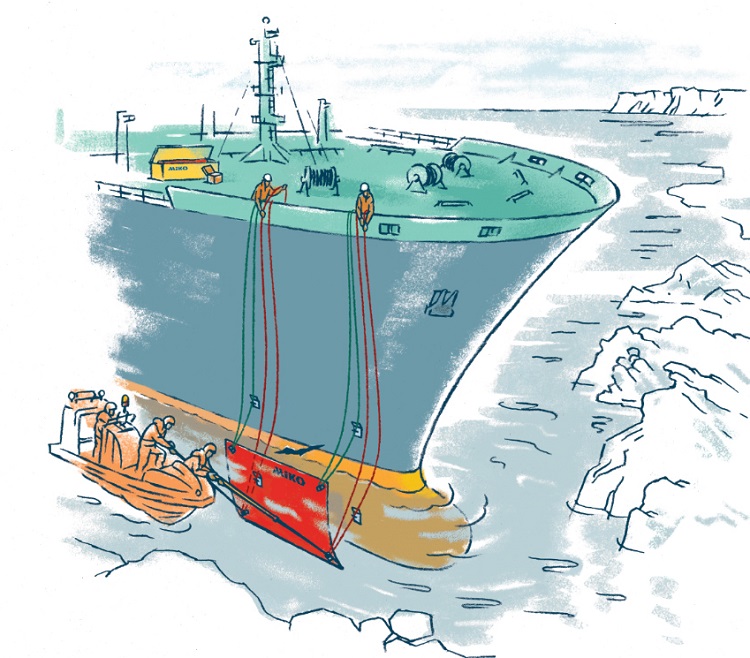

A new system has been developed for applying Miko magnetic patches to ships that have been holed by ice in Polar waters. This is expected to be of particular value to vessels of all types that are applying for Polar Code certification as it will physically demonstrate their preparedness for dealing with hull damage that might be caused by ice.

The new Miko Polar Kit is manufactured in Norway and contains a selection of magnetic patches and high-power magnets that can be lowered and secured over an area of hull damage. Miko patches are well-proven and regularly used around the world where they have prevented the sinking of numerous vessels since their launch in 1997. In an emergency, a patch made from a strong laminate that includes a flexible magnetic layer, can be lowered over the hole where it will stick like a giant fridge magnet. The magnetic adhesion of the patch combined with the outside water pressure closes the hole and keeps it securely in place. Additional high-power magnets might also be used to maintain the seal until the ship is safely in dock.

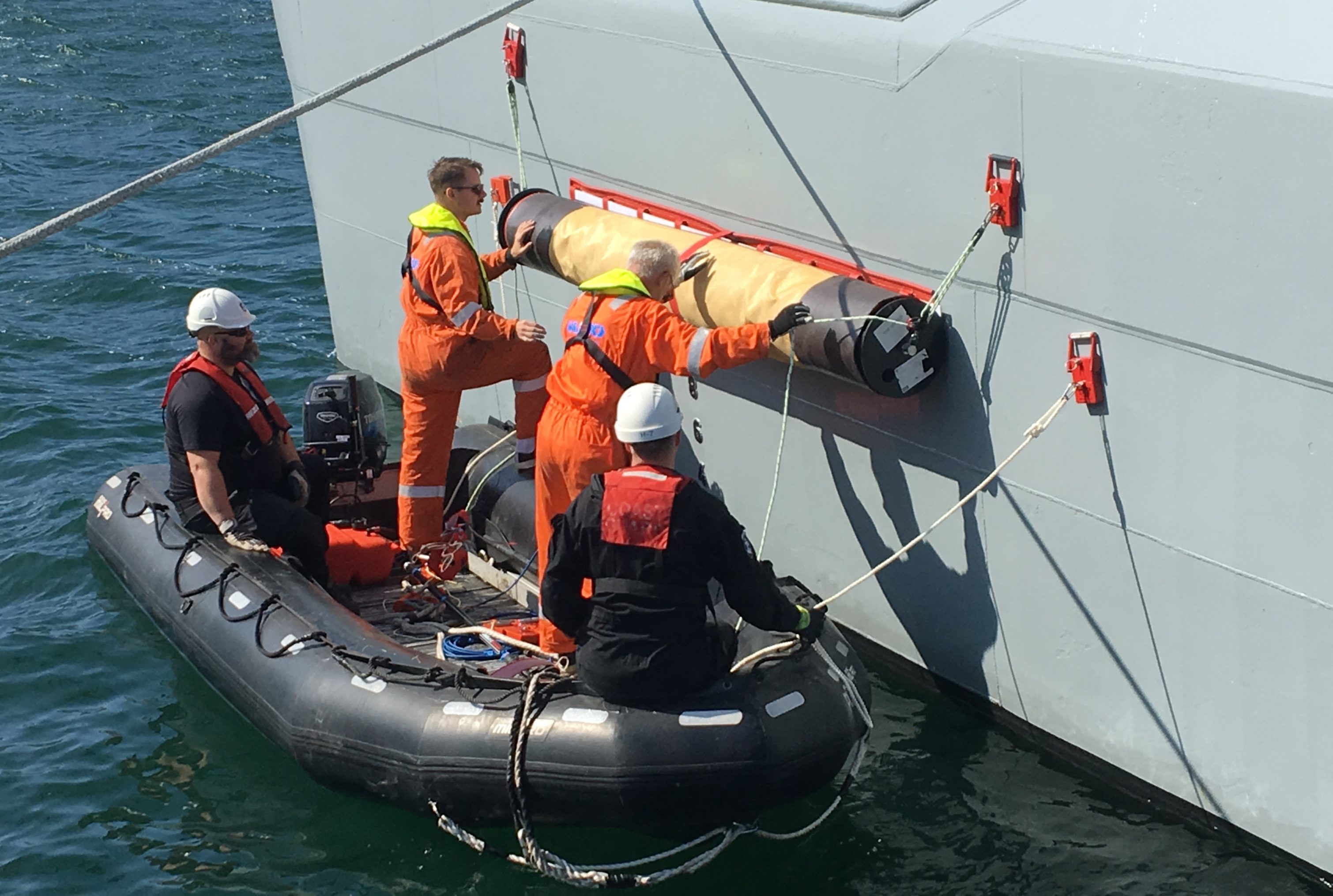

Studies have shown that that ice damage is most likely to occur near or just below the water line so the new Polar Kit has been developed to deal with these situations effectively. It contains a system of handling lines pre-rigged through magnets that are attached to the ship’s hull above and below the damaged area. These enable ships to lower and fasten a magnetic patch over a hole without the use of divers and thereby secure the vessel against water entry.

Increasing Polar traffic prompted the IMO to introduce the Polar Code in 2017 to increase vessel safety and prevent pollution hazards. Ships certified as conforming to the Code are consequently acknowledged as being prepared and technically equipped for dealing with the Polar environment. To achieve this certification ships must undergo a thorough approvals process. They must be able to demonstrate that the ship and crew can cope with Arctic emergencies and are capable of dealing with any problems they might encounter. The dangers of unexpected ice-damage are such that even Ice Class vessels are at risk and must be able to show an ability to deal with incidents should they arise. Miko believes that the new Polar Kit will help demonstrate this ability.

The cruise ship m/v Explorer became the best-known example of a vessel being lost in such circumstances when it sustained a relatively small puncture from hard ice off Antarctica in 2007. Miko’s sales manager, Cato Stoll, recently spoke to Benny Didriksen who was First Officer onboard the Hurtigruta Line vessel M/S NordNorge which witnessed the incident and rescued passengers from the sinking cruise ship. “The crew was unable to stop the in-flow of water and the ship eventually went down,” Stoll was told. “Didriksen told me that if such a patch had been available the outcome would probably have been very different.”

“With greater awareness of the environmental and the safety risks caused by increased shipping in Polar waters, higher standards of safety management are being demanded from ship operators,” said Stoll. “We believe that an ability to deal with ice damage will be seen as an important part of this.”

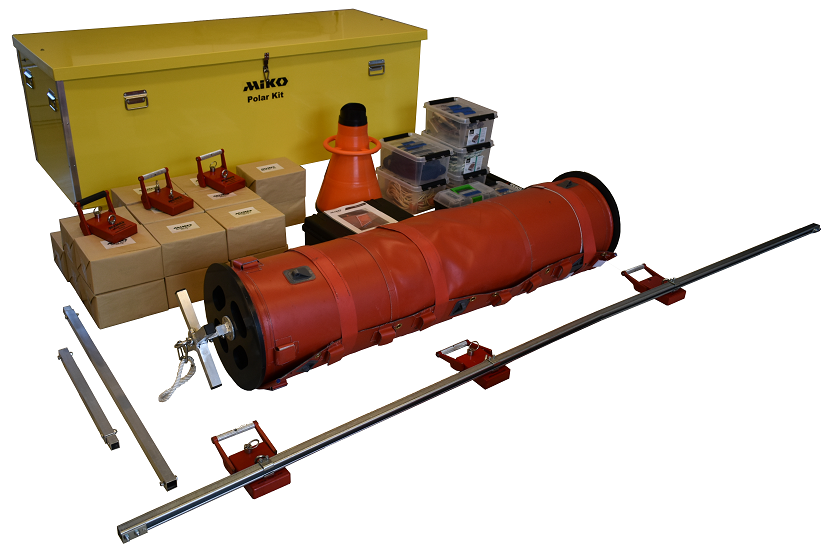

The kit consists of the well known patented and DNV-GL qualified Magnetic Patches, Miko Plaster® and adequate flexible handling– and installation tools enabling subsea installation without divers or ROV’s.

The Miko Marine Polar Kit Contents:

- 1 pcs Miko Marine Special Hybride Plaster 3 x 1 mtr (magnetic plaster frame and flexi shape core)

- 1 pcs Miko Marine Magnetic Plaster® 0.9 x 1.25 mtr

- 20 pcs Miko Marine MAM-003 Anchor Magnets

- 20 pcs (2-box) Miko Marine MPM-001CS Permanent Magnets

- 2 pcs 1.5-5.0 mtr Carbon fiber Telescopic pole for handling of magnets, plaster and camera

- 1 pcs Subsea Camera with 8 mtr cord and Monitor in Pelicase for Location/Inspection of damage

- 1 pcs Tool box with handling ropes, sets of block and tackle for drums for plaster

- 1 pcs Special Installation Drum for plaster

- Fiber glass customized storage boxes

- 1 pcs Installation, User and Maintenance Manual

Gross Weight of the set 380 kg.

Installation Principle

The Miko Polar Kit is a versatile tool which can be used for many different applications. The operating instructions in this chapter provide a typical step-by-step installation guide. Additions and/or deviations may be required for individual cases.

Based on the curvature of the hull at point of damage, decide if the plaster should be installed vertically (long drum), horizontally (short drum) or if the small Miko Plaster is sufficient.

Work sequence

1. Mount the rail onto the hull of vessel with magnets, adjust height with a rubber hammer.

2. Connect lifting tackle with ropes to the rail.

3. Connect drum with plaster to lifting tackle, make sure that the row of MPM magnets are facing away from hull.

4. Hoist drum to max height against rail, fasten pullout rope to bottom attachment point on drum, lower the drum vertically to suited height for plaster to cover the damage.

5. Turn the drum until the vertical row of MPMs click onto the hull, and the plaster is secured.

6. Start the application of the plaster by turning the drum and pulling the pullout rope, adjust height of the drum if necessary.

7. Inspect underwater during the horizontal application of the plaster, use the T-tool on the telescopic pole smoothening the plaster onto the hull as required.

8. Roll the plaster drum until the plaster is rolled out in full length and fastened to the hull.

9. Inspect the plaster, use the T-tool to smoothen out any pockets of air or water between plaster and hull.

10. Secure the plaster using extra MAM-003 magnets.

Possibility for training of the ships crew on board by Miko Marine specialist.