There are many methodes for surface preparation. The best way is Blasting but that is not always possible. For a good adhesion of two-component products there are two inportant rules that is a clean surface and a rough surface.

1) Shot Blasting

For small applications we can recommend the Wencon Blaster (dry-blasting). Available in two different versions. This high quality machine can blast up to SA3 and a rougness of min. 75 microns. We recommend a blasting material Garnet 20-40 (0.85 mm) or 30-60 (0.60 mm) avialable in bags of 25 kilo or big bags of 1 Ton. For almost dustfree blasting there is a Wencon Mouth piece to connect the blasing gun with an industrial vacuum cleaner.

Extra information see downloads.

2) Tercoo

Using a Tercoo tool is a little like blasting but without sand or grit. Tercoo is a rubber disc with hard steel spikes. Tercoo tools are available as a 1, 2 and 3 layer disc for a normal drilling machine and as and 8 layer disc for the special Tercoo machine.

Extra information see downloads

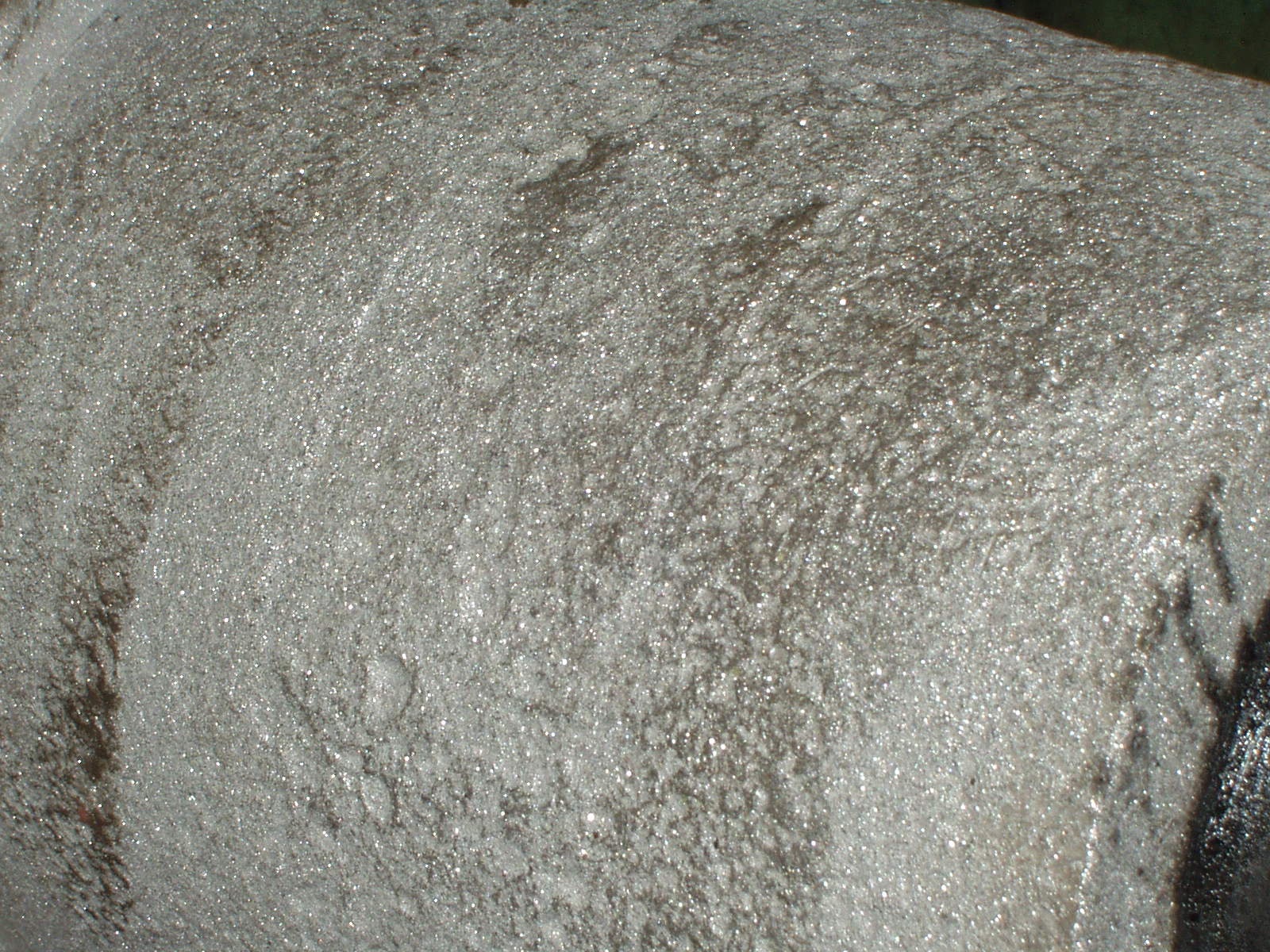

The three pictures below shows the result of the surface preparation of a steel pipe carried out with the Tercoo tools.

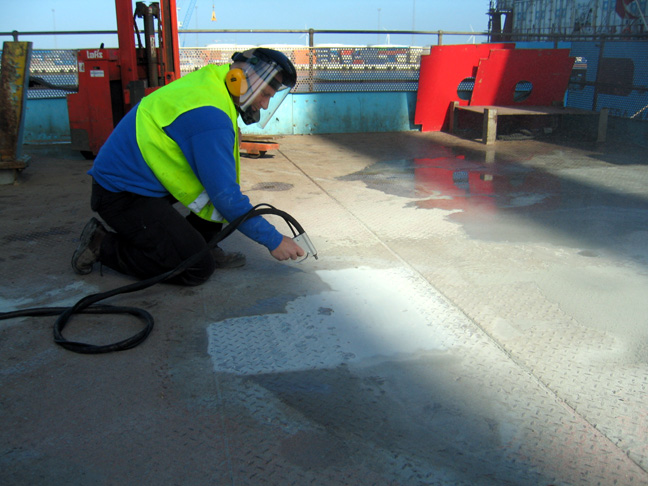

3) Bristle Blaster

This tool removes corrosion and generates an anchor profile by using a specially designed rotary bristle tool. This tool consists of hardened wire bristle tips that are bent forward and dynamically tuned to a hand-held power tool which operates at appoximately 2.500 rpm.

Extra information see downloads

4) Needle Gunning

Needle gunning is a method that has almost been forgotten in the recent years. Or should we say is mostly used for very rough cleaning or removal of rust. It take a lot of time to do a proper job and it is essential that the marks from the sharp needles cover the whole surface so that none of the original surface remains. It is recommendable to steam clean the surface before needle gunning.

Extra information see downloads

5) Grinding

Wheel grinding is an acceptable way in cases, where it is possible to grind the entire surface. Most often when repairing mechanical damages. Corroded surfaces are often in a state where a wheel grinder will only be able to cover a part of the surface, and is therefore not advisable here. When grinding use a course stone and use the Wencon Cleaner after grinding.

6) Turning

When carrying out mechanical repair jobs, turning is often the best and easiest way of preparing the surface. When, for instance repairing a worn shaft damaged by a loose roller bearing, turning to a rough standard should be done prior to degreasing and application.

7) Steam Cleaning

An effective method of removing salt and oil remaining the substrate is to use steam clean. Steam cleaners are available from most plant hire firms. Use steam temperature of approx. 95 degrees C. and repeat the process three times, leaving the substrate to dry for some 15 minutes between each cleaning. Steam cleaning is not sufficient in itself. It must be followed by blasting or done of the other surface preparation methodes.

Steel Brushing

Cleaning by using a steel brush (by hand or machine) we can not recommend. A steel brush leaves a polished surface which will reduce the adhesion of Wencon or other products, two-component or pain etc.

Pay attention due to a good adhesion the the temperature of the surface must be during the coating process at least 3 degrees C above the point of condensation.